MRC Sterilization Autoclaves are available as benchtop or vertical models, for laboratory, hospital, university, dental & clinical use. Available in sizes ranging from 1 liter, 8 liters, 16liter up to 300 liters.

Autoclaves are used for sterilization, disinfection and sterilization of bacteria of:

-Medical tools -Such as surgical tools, dental tools of dentists, tools of veterinarians,

- Tools of pedicurists and beauticians in beauty salons and aesthetics, tools of tattooists,

-Lab tools and instruments in laboratories, hospitals and clinics such as glassware, stands, cages

- For purifying liquids and substances in laboratories in the fields of medicine, biology, food research and more.

The activity is based on the formation of steam at high temperatures and high air pressure. It requires a supply of distilled water.

There are with a vacuum that allow cleaning of vessels with small holes, especially in the dental area.

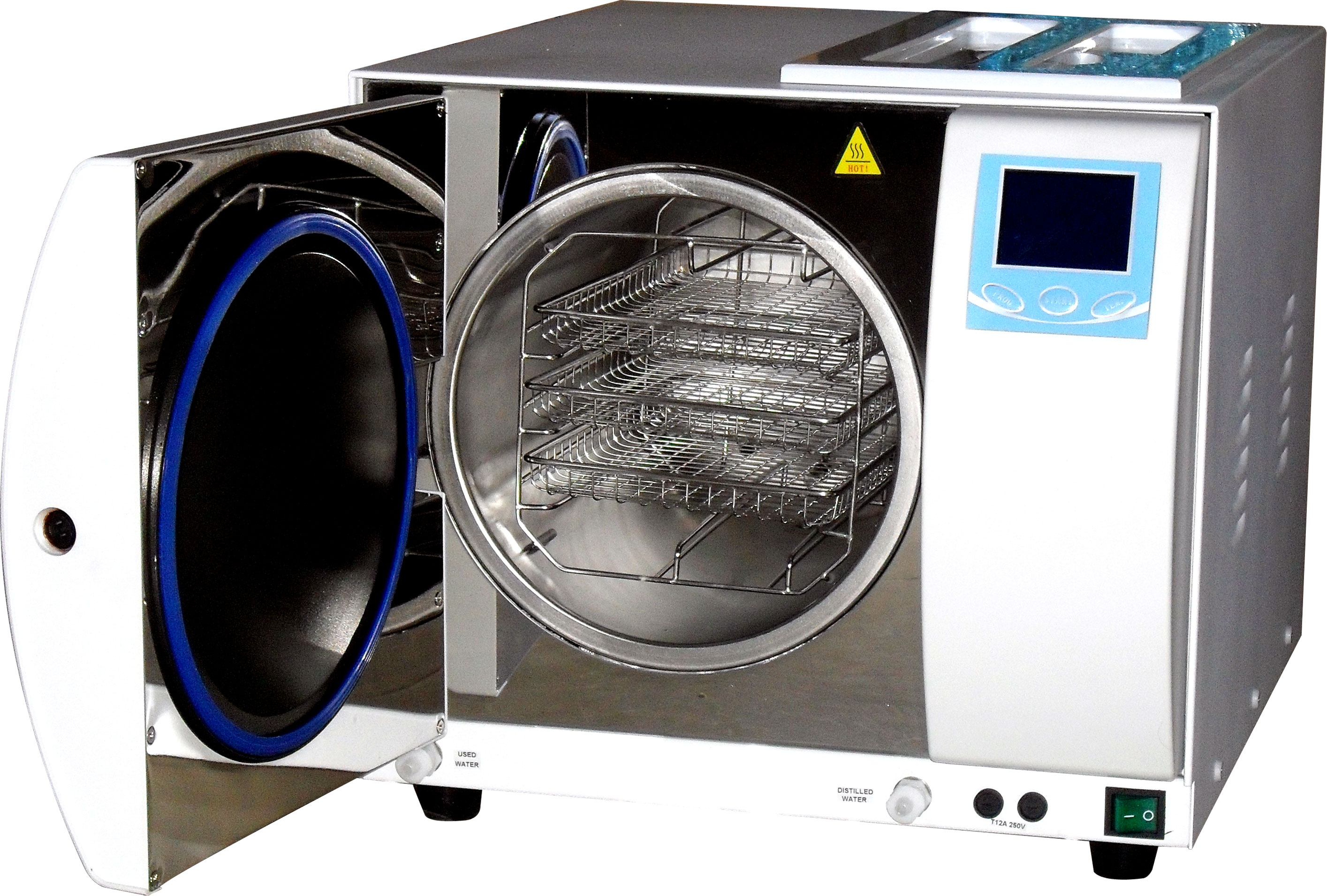

The desktop autoclaves have a door that opens to the front and shelves that are inserted inside

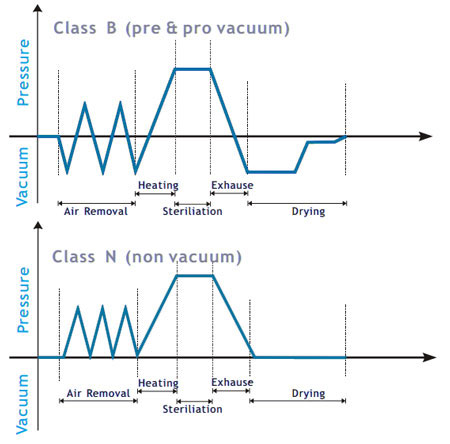

Which Autoclave Class should I use?-Class B & Class N autoclaves

Autoclave class B It has a vacuum cycle. This is the most advanced autoclaves operation, Class B meets stringent requirements and is therefore designed for a wide range of industries. A “class B" must in any case pass a Helix test as per EN 13060 by test body per EN 867-5:2001 According to expert opinion, that can only be achieved with According to expert opinion.

Autoclace class N -Without vacuum cycle. If you only sterilize unwrapped nonhollow instruments, you only need an autoclave capable of running class N cycles.

MRC provide special autoclaves for dental clinics.

Industrial Autoclave

VOLUME (L)- 146-1000

For hospitals, biology, microbiology, pharmaceutical and biotechnology laboratories.The autoclave includes a steam system that raises the temperature to 121/134 Celsius and kills the bacteria in a short time of minutes.

How Does an Autoclave Work?

The operation is similar to a pressure cooker in the kitchen. The door is locked to create an airtight chamber, and all the air inside this room is replaced by steam. The steam pressure causes the sterilization activity. After the rotation operation, the steam disappears and the device can be removed.

What is the Correct Temperature Of The Autoclave?

Usually, the correct temperature is 121 ° C. But there are some that can even reach 134 ° C.

How long does the sterilization operation take?

It depends on the device and the size we want to sterilize. If the device is larger, we will need more time for sterilization.

Types of Autoclave:

-Class N

-Class B

-Vertical

History

The autoclave was invented In 1879, medical practitioners began to see sterile surgery differently, and autoclave soon became an essential part of the medical field, both in clinics and hospitals.

Autoclave Parts and Components

-pressure cabinet

-Hood / Door

-Manometer

-Safety valve

- Steam generator

-cooler

Vertical Autoclave

A vertical autoclave is a type of sterilization device used to kill bacteria, viruses, fungi, and spores by applying heat and pressure. Autoclaves are widely used in laboratories, hospitals, research facilities, and industrial applications to sterilize equipment, glassware, and medical instruments.

Key Features of Vertical Autoclaves:

Vertical Orientation: In a vertical autoclave, the lid opens from the top, and items are placed inside from above. This design is useful for laboratories or medical settings with limited floor space.

Sterilization Process: The autoclave uses high-pressure steam (usually at 121°C and 15 psi for a standard cycle) to sterilize the contents.

Who is Autoclave suitable for?

Our autoclaves are suitable for Laboratories, research institutes, various clinics, beauty and aesthetics institutes, doctors, dental clinics, jewelers, various industries and more

Autoclaves For Sale

MRC supply a wide range of Autoclaves. Different sizes and volumes. Contact us