A cold trap is an essential accessory for vacuum pump systems, especially in applications where the removal of volatile substances or moisture is necessary. It serves as a barrier to prevent these vapors from entering and potentially damaging the vacuum pump. Understanding how cold traps work and their benefits is crucial for ensuring the efficiency and longevity of vacuum systems.

How Does a Cold Trap Work?

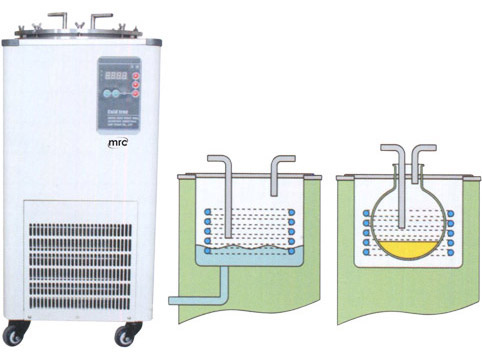

Cold traps operate on the principle of condensation. When vapors pass through the cold surface of the trap, they lose heat energy and condense into liquid form, which is then collected. This prevents the vapors from reaching the vacuum pump and causing contamination or damage. There are various types of cold traps available, including dry ice traps, liquid nitrogen traps, and mechanical refrigeration traps, each with its own mechanism of cooling.

Benefits of Using a Cold Trap

The use of a cold trap offers several advantages. Firstly, it prevents backflow of vapors into the vacuum pump, thereby maintaining a clean and efficient system. Additionally, it protects the vacuum pump from corrosive or harmful substances, extending its lifespan. Furthermore, cold traps ensure the purity of samples by removing unwanted contaminants, making them ideal for laboratory and industrial applications.

Choosing the Right Cold Trap

Selecting the appropriate cold trap depends on factors such as the type of vacuum pump, the volume and nature of the sample, and the desired level of cooling. Popular brands like Labconco, Buchi, and Chemglass offer a range of cold traps suitable for different requirements.

Installation and Maintenance

Installing a cold trap involves positioning it between the vacuum pump and the sample source and connecting the necessary tubing. Regular maintenance, including cleaning and checking for leaks, is essential for optimal performance and preventing potential issues.

Applications of Cold Traps

Cold traps find wide-ranging applications in laboratories, where they are used in processes such as vacuum distillation, freeze drying, and solvent recovery. They are also utilized in industrial settings for degassing, solvent trapping, and environmental testing.