A cold trap is a critical device used in scientific and industrial settings to condense or freeze out vapors from a gas stream. This equipment prevents contamination or damage to vacuum systems, pumps, or sensitive instruments. Think of it as a sophisticated bouncer at a nightclub, allowing only the right molecules to pass while stopping the unwanted ones in their tracks.

Cold traps are indispensable in applications that demand clean and efficient vacuum operations. Whether it's freeze drying pharmaceuticals or conducting chemical reactions under controlled conditions, cold traps ensure systems run smoothly without interruptions caused by contaminants.

What types exist?

Passive Cold Traps

These traps rely on natural cooling, such as surrounding them with ice or dry ice, to condense vapors. While cost-effective, they are less efficient for high-demand applications.

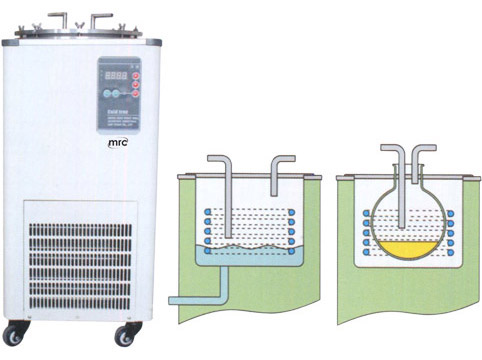

Active Cold Traps

Active cold traps are powered by refrigeration systems to achieve lower temperatures, making them ideal for heavy-duty operations requiring precise vapor trapping.

Cryogenic Cold Traps

These advanced traps use cryogenic coolants, like liquid nitrogen, to reach ultra-low temperatures. They’re often employed in applications requiring extreme efficiency in vapor collection.

How Cold Traps Work

Cold traps operate by cooling the surface to a temperature at which specific vapors condense. When the vapors contact the cooled surface, they turn into a liquid or solid state, effectively removing them from the system.

Components

- Cooling Element: The primary component responsible for reducing temperature.

- Collection Chamber: Where condensed vapors are stored.

- Insulation: Ensures energy efficiency and minimizes heat exchange.

Applications of Cold Traps

Vacuum Systems

Cold traps protect vacuum pumps by capturing oil, water, or chemical vapors that could degrade the pump's efficiency.

Freeze Drying

In pharmaceutical and food industries, cold traps remove moisture from products, preserving them for long-term storage.

Chemical Synthesis

They capture by-products in reaction chambers, ensuring clean outcomes and protecting sensitive reagents.

Environmental Monitoring

Cold traps are used to capture and analyze volatile organic compounds (VOCs) in air samples.

What to take into account

Consideration of Temperature Range

Different vapors condense at different temperatures. Choose a trap that aligns with the requirements of your application.

Compatibility With Existing Systems

Ensure the cold trap integrates seamlessly with your vacuum or chemical processing equipment.

Maintenance Requirements

Opt for designs that are easy to clean and maintain to ensure long-term reliability.

Benefits of Using Cold Traps

-Improved Equipment Longevity:By trapping harmful vapors, cold traps extend the lifespan of pumps and other equipment.

-Enhanced System Efficiency:They maintain system performance by preventing clogs and contamination.

-Reduced Contamination Risks:Cold traps act as a safeguard, keeping unwanted materials out of critical processes.