Application of Laboratory filtration

Filtration is an important process in various industries and scientific applications. Some common applications of filtration include:

-Filtration of aqueous solutions is commonly used to remove suspended solids, microorganisms, and other contaminants. For example, drinking water is often filtered to remove impurities that can affect the taste and safety of the water.

-In the field of biotechnology, filtration is used to clarify cell culture media and buffers. This is important in maintaining the purity and stability of cell cultures, and ensuring accurate results in experiments.

-In chemical synthesis, filtration is used to separate solid products from reaction mixtures. This is important in the purification process and helps to improve the quality of the final product.

-In industrial processes, filtration is used to remove impurities from solvents. For example, roughing filtration is used to remove larger impurities from industrial solvents, which helps to extend the life of downstream filters and prevent clogging.Vacuum filtration

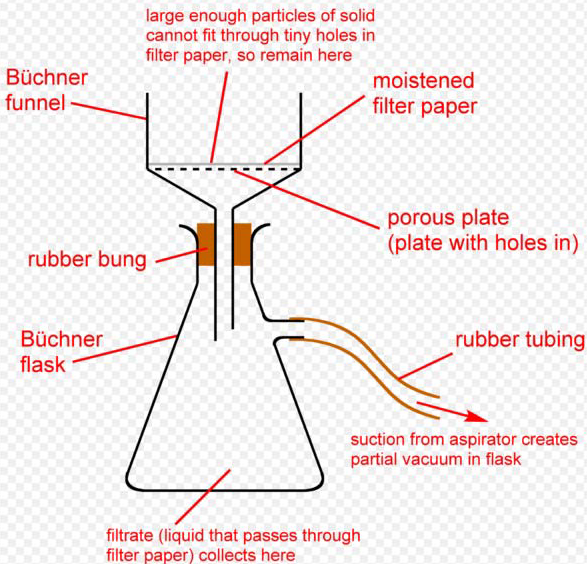

Vacuum filtration is a laboratory filtration technique that uses a vacuum to generate a negative pressure in a container and separate solid particles from a liquid. The process is based on the principle that a vacuum can create a negative pressure in a container, which will cause the liquid to pass through a membrane, such as a filter paper, and into the container.

In a vacuum filtration setup, a filter paper is placed on the bottom of a funnel, and the funnel is positioned above a flask. The flask is then attached to a vacuum pump, which creates a negative pressure within the flask. This negative pressure causes the liquid to be pulled through the filter paper and into the flask, while the solid particles are trapped on the surface of the filter paper.

The negative pressure created by the vacuum pump accelerates the flow of liquid through the membrane, which helps to improve the efficiency of the filtration process. Additionally, the vacuum filtration process allows for the use of a smaller filter paper, as the vacuum helps to overcome the pressure required to force the liquid through the filter paper.

Vacuum filtration is a powerful and efficient method for separating solid particles from a liquid. The negative pressure created by the vacuum pump accelerates the flow of liquid through the membrane, which helps to improve the efficiency of the filtration process.Suction filtration is a chemistry laboratory technique that allows for a greater rate of filtration. Whereas in normal filtration gravity provides the force which draws the liquid through the filter paper, in suction filtration a pressure gradient performs this function. This has the advantage of offering a variable rate depending on the strength of the pump being used to extract air from the Büchner flask. Care must be taken not to use such a strong vacuum that the filter paper rips (in which case all the solid will be lost back into the solvent) or in extreme cases the glass flask breaks.

Vacuum-filtration-diagram:

VACUUM FILTRATION SET,COMPLETE SYSTEM, 3 PLACES

In many laboratories, liquids are filtered:

In laboratories that handle drinking water, water desalination, and waste water, it is customary to filter aqueous solutions to identify suspended solids and various microorganisms.The filtration is performed by extremely dense filter paper with holes of 1 micrometer in diameter and less. For this purpose, a vacuum pump and filter cups are used into which the tested liquid is poured.

The cups differ from each other in the material they are made of: filter holder made of disposable plastic, filter holder made of glass or stainless steel that can be sterilized and used in water laboratories, chemical laboratories

For separations of chemical and industrial solvents.

A waste vacuum bottle for laboratory use is a specialized container designed to safely collect and dispose of liquid waste generated during laboratory experiments and procedures. These bottles are an essential component of laboratory safety and efficiency, ensuring that hazardous or non-hazardous waste is managed properly.

MULTI-BRANCH LABORATORY FILTRATION SYSTEMS

A Multi-Branch Laboratory Filtration System typically refers to a filtration setup in a laboratory that involves multiple branches or pathways for filtration. This type of system is designed to allow concurrent or sequential filtration of different samples or substances through various filter units or setups.

Multi-Branch Laboratory Filtration Systems consist of interconnected branches that allow for simultaneous filtration of multiple samples. The primary purpose is to streamline the filtration process, enhancing efficiency and reducing the time required for experiments.

Laboratories involved in pharmaceutical research, environmental testing, and food and beverage quality control find these systems invaluable. The ability to conduct multiple filtrations concurrently not only saves time but also optimizes resources.

Advantages of Multi-Branch Filtration

Enhanced Efficiency

The ability to filter multiple samples at once significantly improves the overall efficiency of laboratory processes. Researchers can accomplish more in less time, accelerating project timelines.

Simultaneous Filtration

Unlike traditional filtration systems, multi-branch setups enable researchers to address several samples simultaneously. This feature is particularly beneficial in high-throughput environments.

Applications in Various Industries

The versatility of multi-branch filtration systems makes them applicable across diverse industries.

Pharmaceutical Research

In pharmaceutical research, where precision and purity are non-negotiable, these systems ensure the filtration of pharmaceutical compounds is efficient and meets rigorous standards.

Environmental Testing

For laboratories involved in environmental testing, the ability to handle multiple samples simultaneously enhances the throughput of water and air quality assessments.

Food and Beverage Quality Control

Quality control in the food and beverage industry demands rigorous testing. Multi-branch filtration systems offer a solution to process numerous samples efficiently, ensuring adherence to quality standards.

MULTI-BRANCH MANIFOLDS

A laboratory manifold is a device used to filter liquids in a laboratory setting. It typically consists of a series of parallel channels that are connected to a single outlet. This allows multiple samples to be filtered simultaneously, increasing efficiency and reducing the time required for filtration.Multi-branch manifolds are specialized systems designed to distribute or collect fluids or gases in laboratory settings. Unlike traditional single-branch systems, they offer a network of interconnected pathways, allowing for more intricate control and versatility in experiments.

The manifold funnels can be made of various materials such as glass, plastic, or stainless steel. The choice of material will depend on the application and the type of liquid being filtered. For example, glass funnels are suitable for visible inspection of the filtrate, while stainless steel manifolds are more durable .

The manifold typically includes 3 or 6 funnels, which can filled with 47mm filter paper membranes. The filter media can be selected based on the size and type of particulates or molecules that need to be removed from the liquid.

Manifold can be used in various applications such as cell harvesting, protein purification, or sterilization of liquid.

Applications in Laboratories

The versatility of multi-branch manifolds is reflected in their widespread applications across various laboratory disciplines.

A. Analytical Chemistry

In analytical chemistry, where precision is paramount, these manifolds facilitate the simultaneous analysis of multiple samples, expediting research workflows and ensuring accurate results.

B. Biochemical Research

Biochemical laboratories benefit from the flexibility offered by multi-branch manifolds, allowing for controlled mixing of reagents and the efficient execution of complex protocols.

C. Pharmaceutical Development

In the pharmaceutical industry, where stringent protocols govern experimentation, multi-branch manifolds contribute to the development of drugs by enabling precise control over the mixing and distribution of pharmaceutical compounds.

Advantages of Multi-Branch Manifolds

The adoption of multi-branch manifolds is driven by their compelling advantages, revolutionizing laboratory practices.

Increased Efficiency

By facilitating simultaneous processes, these manifolds reduce experimental time, leading to enhanced productivity and resource optimization.

Precision and Accuracy

The intricate control provided by multi-branch manifolds ensures that experiments are conducted with the highest level of precision, minimizing errors and improving the reliability of results.