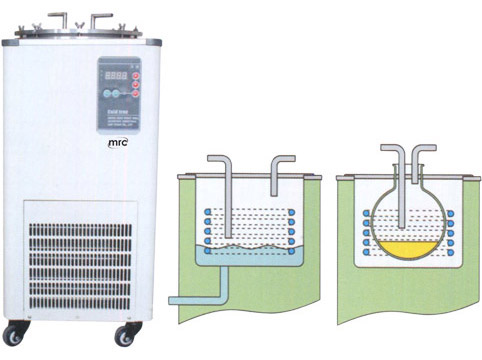

Cold traps are devices designed to trap and condense volatile substances, such as water, solvents, or gases, by cooling them down to a temperature below their boiling point. They are widely used in vacuum systems to prevent contamination of the vacuum pump by trapping volatile substances before they can reach it.

Applications of Cold Traps

Cold traps are used in a wide range of applications, including:

Vacuum Systems

In vacuum systems, cold traps are used to prevent contamination of the vacuum pump by trapping the volatile substances before they can reach it. They are commonly used in semiconductor manufacturing, chemical processing, and analytical instrumentation.

Gas Chromatography

Cold traps are also used in gas chromatography to trap unwanted substances, such as water or oxygen, from the sample before it enters the column. This ensures that the column remains clean and free from contamination, resulting in better separation and more accurate analysis.

Environmental Monitoring

Cold traps are used in environmental monitoring to trap volatile organic compounds (VOCs) from the air or water samples. This is important for detecting and analyzing pollutants in the environment, such as benzene, toluene, and xylene.

Benefits of Using Cold Traps

There are several benefits to using cold traps, including:

Improved Pump Performance

Cold traps help improve the performance and longevity of vacuum pumps by preventing contamination and reducing the wear and tear on the pump's components.

Better Separation and Analysis

Using cold traps in gas chromatography improves the separation and analysis of the sample, resulting in more accurate and reliable results.

Enhanced Safety

Cold traps can help prevent the release of hazardous substances into the environment, protecting both people and the environment.

Maintenance and Care

Proper maintenance and care are essential to ensure the optimal performance of cold traps. Here are some tips for maintaining and caring for cold traps:

Regular Cleaning

Cold traps should be cleaned regularly to remove any accumulated contaminants or debris. This can be done by soaking the trap in a cleaning solution or wiping it down with a solvent.

Check the Coolant

The coolant level and condition should be checked regularly to ensure the trap is working at optimal temperatures. Low coolant levels or contaminated coolant can affect the trap's performance.

Replace Components

Cold traps have several components, such as o-rings and seals, that may need to be replaced periodically. It's essential to follow the manufacturer's guidelines for replacement and maintenance.