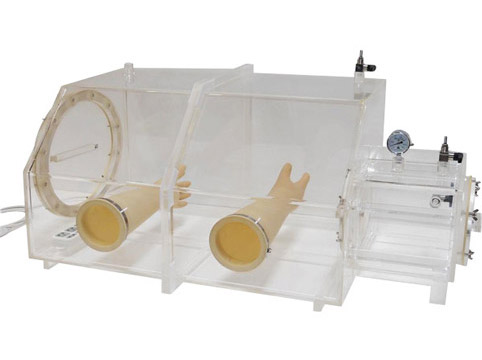

A laboratory glove box is a sealed enclosure designed to create and maintain an environment where the air inside is filtered and replaced with sterile air. This allows for sensitive operations to be carried out without contamination. Glove boxes are used in various laboratories and pharmaceutical production facilities.

Sterile gloves and gowns are typically worn when working inside a glove box. The gloves are attached to the box with special sleeves that allow for a tight seal. This prevents outside contaminants from coming into contact with the box's air.

You can use glove boxes for various purposes, such as handling hazardous materials, working with sensitive equipment, or carrying out delicate operations.

In a laboratory setting, glove boxes are often used for handling radioactive materials or working with hazardous chemicals. In a pharmaceutical production facility, you may use them for packaging and labeling operations. Isolator boxes deliver an inert gas atmosphere for Glove Boxes which is necessary to maintain product sterility.

In addition to keeping the air inside sterile, glove boxes can also be used to control temperature and humidity. This is important for operations that require precise conditions, such as working with delicate electronic components or sensitive biological samples.

Types of Glove boxes

A containment Laboratory glove box is an enclosed workspace that provides operator protection from hazardous materials while allowing access to the box's interior via glove ports. You can use glove boxes for various tasks, such as handling radioactive materials, working with hazardous chemicals, or performing delicate tasks that require a sterile environment. These glove boxes allow air circulation via HEPA or ULPA filtration to keep the box's interior clean.

Isolation glove boxes offer a diverse approach to glove box selection. This type of glove box is used when you need to protect the operator from contact with the outside environment. Isolation boxes come in various sizes and can be outfitted with different ventilation systems.

The type of chemistry being done in the lab, as well as the objects or materials being generated, dictate what kind of construction material to use, including:

- ●ABS plastic for basic chemical compatibility

- ●Polycarbonate for better chemical and heat resistance

- ●PVC or Teflon-coated materials for use with aggressive chemicals

- ●Stainless steel for autoclave compatibility or other extreme conditions

- ●Aluminum for ESD (electrostatic discharge) control

- ●Lead for shielding against radiation

An open-loop or single-pass box creates one-way airflow, which is less efficient than a closed-loop system. However, it is simpler and cheaper to construct and does not require as much maintenance. Open-loop systems are often used in industrial settings where air quality is not as critical.

Combination boxes enable you to create a closed- and an open-loop system. This means that they can be used in various applications, from simple on/off control to more complex systems that require feedback. Combination boxes are a versatile option for many different types of projects.

The anaerobic chamber, for example, is a specialized container designed to create an oxygen-free environment. Anaerobic chambers are typically used for tasks such as working with bacteria or other microorganisms that cannot tolerate oxygen.

Stainless steel boxes come in many different grades, the most common being 304 and 316. The type of stainless steel you choose will depend on the chemicals you use and the temperatures you need to maintain.

Size of the laboratory Glove Box

The size of the glove box you need will vary depending on the project you are working on. For smaller projects, a benchtop model may be sufficient. Larger projects may require a floor-standing model. You can also use a portable version for fieldwork or when working in a space that is not permanently set up for glove box use.

Functions Of Laboratory Glove Boxes

Within the containers themselves, you may design environments to fit the current project's needs. For example, an inert gas such as nitrogen or argon can be used to prevent the oxidation of sensitive materials.

The most common gasses used in glove boxes are:

- ●Nitrogen

- ●Argon

- ●Helium

- ●Hydrogen

- ●Carbon dioxide

- ●Methylene chloride

- ●Ethanol

These can be employed in different contexts to create the desired effect. For example, using a nitrogen-rich atmosphere can help prevent fires. We can also create negative pressure conditions to prevent contaminants from entering the box.

A fluctuating pump pulls a vacuum on the system in pressure control systems, balanced with an adjustable gas flow. This maintains constant pressure in the box, which is important for keeping delicate materials from being damaged.

Leak-tight fittings are essential for creating a safe and effective glove box. All connections, including those between the gloves and the ports, should be sealed to prevent any gas or liquid from escaping.

Glove boxes come in various shapes and sizes, but they all serve the same purpose: to provide an isolated environment for delicate tasks. For high-relative humidity applications, you can use a desiccator to remove moisture from the air. If the procedure is within the standard low-RH range, then a regular glove box with an activated carbon filter will work.