Laboratory vacuum pumps are the unsung heroes of scientific research, quietly working behind the scenes to facilitate crucial experiments and processes. However, like any machinery, these pumps require careful attention and maintenance to ensure optimal performance and a longer lifespan.

Laboratory vacuum pumps are devices designed to create and maintain a vacuum in a laboratory setting. They play a vital role in various applications, including filtration, distillation, and degassing.

Importance of Proper Maintenance

Proper maintenance is essential for the efficiency and longevity of laboratory vacuum pumps. Neglecting maintenance not only leads to decreased performance but also increases the risk of malfunctions and costly repairs.

Types of Laboratory Vacuum Pumps

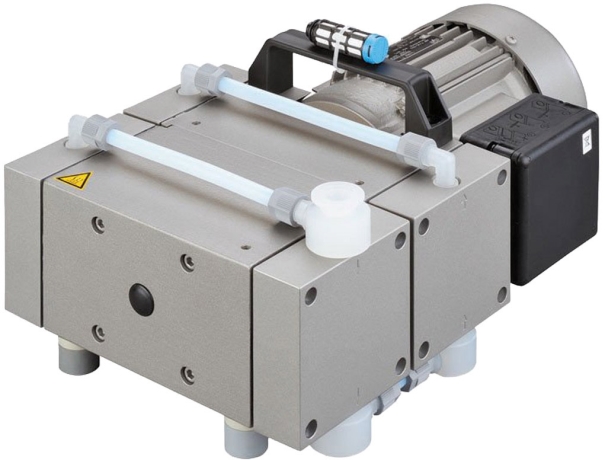

A. Diaphragm Pumps

Diaphragm pumps are known for their oil-free operation, making them suitable for applications where contamination is a concern. Regular inspection of diaphragms is crucial to prevent leaks and ensure consistent performance.

B. Rotary Vane Pumps

Rotary vane pumps are widely used for creating a medium vacuum. Understanding the lubrication requirements and timely oil changes are key to maintaining the smooth operation of these pumps.

C. Scroll Pumps

Scroll pumps, with their hermetic design, are gaining popularity in labs. Periodic cleaning of scrolls and monitoring scroll tip seals are vital for preventing performance degradation.

Understanding the Working Mechanism

Basics of Vacuum Pump Operation

Laboratory vacuum pumps operate by removing air from a closed system, creating a vacuum. Understanding the fundamental principles of this operation is crucial for effective troubleshooting and maintenance.

Common Components

Knowing the key components of vacuum pumps, such as inlet filters and exhaust systems, helps in targeted maintenance. Regularly inspecting and cleaning these components ensures uninterrupted pump performance.

Regular Inspection and Cleaning

A. Importance of Regular Check-ups

Regular inspections help identify potential issues before they escalate. Checking for wear and tear, loose fittings, and unusual noises should be part of routine maintenance.

B. Cleaning Procedures for Various Pump Types

Different pump types require specific cleaning procedures. Following manufacturer guidelines and using appropriate cleaning agents are essential to prevent damage during the cleaning process.

Lubrication Practices

A. Types of Lubricants

Choosing the right lubricant is critical for the smooth operation of vacuum pumps. Some pumps require oil, while others operate oil-free. Understanding the lubrication needs of your specific pump is essential.

B. How and When to Lubricate

Establishing a lubrication schedule based on the pump type and usage is key. Over-lubrication can be as detrimental as under-lubrication, so a balanced approach is crucial for optimal performance.

Temperature Control

A. Effects of Temperature on Pump Performance

Temperature can significantly impact the efficiency of laboratory vacuum pumps. Understanding the ideal operating temperature range and implementing cooling systems can prevent overheating.

B. Cooling Systems

Incorporating cooling systems, such as fans or water jackets, helps regulate the temperature of the pump. Regularly checking and maintaining these systems is vital for consistent pump performance.

Monitoring Vacuum Levels

A. Importance of Vacuum Level Monitoring

Monitoring vacuum levels ensures that the pump is operating within the required parameters. Sudden changes in vacuum levels can be indicative of issues that need immediate attention.

B. Using Gauges and Sensors

Utilizing vacuum gauges and sensors is a proactive way to monitor performance. Regular calibration and replacement of faulty gauges are essential for accurate readings.