Micrometers are instruments for very accurate measurements. Measurement in the range of 1000 cm.

There are several types of micrometers that are designed to measure different types of objects or spaces: Outside Micrometer,Inside Micrometer,Depth Micrometers,digital Micrometers.The measurement depends on what needs to be measured. As the size of a pipe or vessel

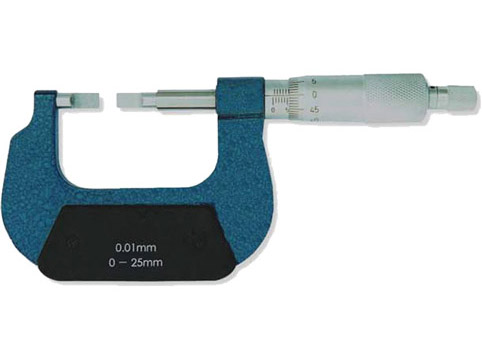

What is a Micrometer

This is a very accurate measuring instrument. It is used to measure objects of very small size with great accuracy. Typically, they have a minimum error, which can measure even up to hundreds (0.01 mm) or milliseconds (0.001 mm) of a millimeter.The micrometer has a simple principle. It is based on a screw for changing a small displacement precisely due to its scale. The user of this type of tool will be able to thread the screw until the edges of the measurement make contact with the object surfaces to be measured.

Types of Micrometer

Digital-They are electronic, with an LCD screen where the reading is displayed for great convenience

Mechanical-They are completely manual, and the reading is done by interpreting a recorded scale

Application

Machine Shops and Manufacturing: Used in machine shops and manufacturing industries to measure the dimensions of machine parts, components, and tools with high precision. This ensures that the manufactured parts meet the required specifications and tolerances.

Engineering and Metrology: In engineering fields such as mechanical, aerospace, and automotive engineering, micrometers are indispensable for measuring the dimensions of critical components, ensuring proper fit, and maintaining quality standards.

Quality Control and Inspection: Micrometers Are important in quality control and inspection processes across various industries. They are used to verify the accuracy of manufactured parts, detect deviations from specifications, and ensure consistency in production.

Laboratories and Research: In scientific research and laboratory settings, They are used for precise measurements in fields such as physics, materials science, and biology. They are essential for conducting experiments, analyzing data, and ensuring the accuracy of research findings.

Tool and Die Making: Micrometers are indispensable tools for toolmakers and die makers in the fabrication of precision tools, molds, and dies. They enable precise measurements during the manufacturing process, ensuring the dimensional accuracy of the final products.

Automotive and Aviation Maintenance: In the automotive and aviation industries, They are used for maintenance, repair, and overhaul tasks. They are employed to measure critical components such as engine parts, bearings, and fasteners to ensure proper functioning and safety.

Watchmaking and Jewelry: Used in watchmaking and jewelry industries for measuring tiny components and intricate details with exceptional precision. They enable craftsmen to produce high-quality timepieces and jewelry pieces to exact specifications.

Education and Training: Micrometers are valuable educational tools for teaching precision measurement techniques in technical schools, colleges, and vocational training programs. They help students develop essential skills in dimensional metrology and precision engineering.