TOS series orbital shakers are designed to shake Arlenmeier and test tubes in a circular shaking motion at a slow speed of 25-500 rpm.

In continuous work and heavy loads of a large number of Erlenmeyers, containers and test tubes.

Uses of an orbital shaker

These shakers are popular in laboratories of beverage factories, algae cultivation, biological laboratories, manufacturers of vitamins and food supplements,

Life sciences laboratories, cell growth, and plant and seed laboratories.

How does orbital shaker work

The shaker contains an oscillating board that hold the vessels as the device shakes to blend, agitate, or mix the substances in the vessels

How to Choose the Appropriate Orbital Shaker for Your Lab:

The orbital shaker is important for physics and biology studies. Microorganisms can be cultured, chemicals can be agitated, and general pairing and blending can all be done using laboratory equipment.Shakers are available in a variety of sizes, textures, and forms

What speed do you need?

Some shake at 500 rpm, whereas others shake at 15 rpm. Depending on whether the user interface is digital or analog, the speed duration varies. Digital orbital shakers are more accurate in terms of speed than analog versions. If the device is layered, the speed could also be regulated.

What Temperature Range Do you need?

It's critical to choose an orbital shaker with the temperature range you'll have to satisfy your specific development needs.

What Vessels do you need to shake?

It's critical to make a list of all the labware you'll have to shake. Every operation requires a different set of attachments and screws.

How many types of Vessels do you want to shake at once?

The majority of companies have constructed systems that can only shake one type of vessel, such as a flask. Clamps are already mounted on such levels, which enable full capacity.

Universal systems, on the other hand, allow you to use labware of varying sizes on the same platform. It has mounting holes so you can add and swap test tube racks and clamps as needed.

If more than one person will be utilizing the shaker, additional platforms may be useful.

What Orbit Diameter is right for you?

You can choose the orbit diameter of the shaker after you've decided what sort of vessel(s) you'll be shaking. When buying a shaker, the size of the orbit is an important factor to consider.

Specific orbit sizes are beneficial for certain vessels and culturing purposes. The size of the shaker's orbit has a significant effect on the oxygenation and ventilation of your growth material.

The orbit diameter of most shakers on the market is between 2.5 and 5.1 cm. For most applications, a 2.5-centimeter orbit is sufficient, although experiments with volumes exceeding 2 liters or cells that are susceptible to stress will profit from a bigger orbit.

Microcentrifuge tubes, microplates, as well as other extra-tiny vessels benefit from tiny orbit diameters of less than 1 cm.

How much weight will the shaker bear?

Weight restrictions apply to all orbital shakers. Consider a model with such a threefold divergent driving mechanism if the shaker is going to be subjected to a lot of work. Single eccentric driving mechanisms are more suited to low-load applications.

If you're undecided about whether to go with a digital or analog shaker, don't fret. Things are going to get a whole lot easier. As we all know, these two forms of user interfaces have a lot of distinctions. Analog orbital shakers are less expensive than their digital counterparts, however, they have a smaller variable speed.

Digital shakers are regarded as servicing, whereas analog shakers require regular service. This could be caused by the necessity to change the brushes in the analog systems' motors.

Analog shakers have fewer functions than digital shakers. Temperature and speed alerts are among them, as is the ability to upload data to a computer.

There are several different types of orbital shakers to choose from. Examine the issues above and evaluate the available alternatives before making your purchase.

Orbital Shakers For Purchase

MRC offers a wide range of orbital Shakers at attractive prices for purchase.

Orbital Shakers-Drive Mechanism

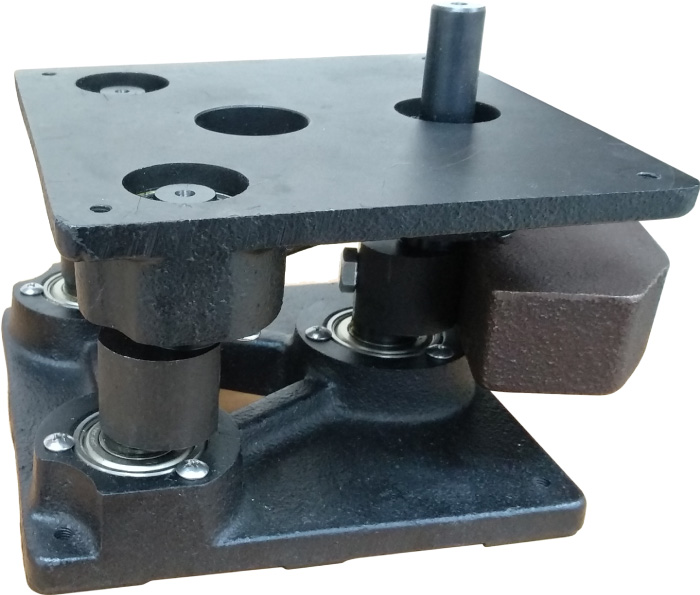

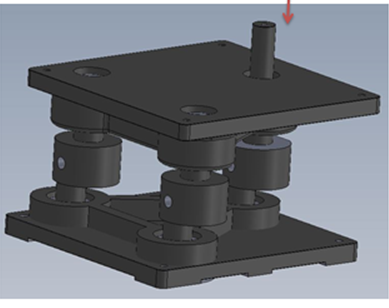

Dependable operation is due to superior design and precision fabrication , the cast iron drive mechanism

triple-eccentric counterbalanced drive support heavy workloads,for long test time of many days and weeks.

The drive shafts made with high tolerance of microns to ensure stable and vibration free operation for heavy loads and high speed applications.

, MRC shakers will provide maintanance-free operation for many years to come.