applications vary from fluid dispensing (the vessel is used as fluid container), to vacuum or pressure chambers for testing components and equipment’s.

Customers for these products vary from Medical and Pharma companies all the way to electronic manufacturers for aerospace, consumers (mobile phones, smart watches, etc…), automotive, racing, medical device, etc…

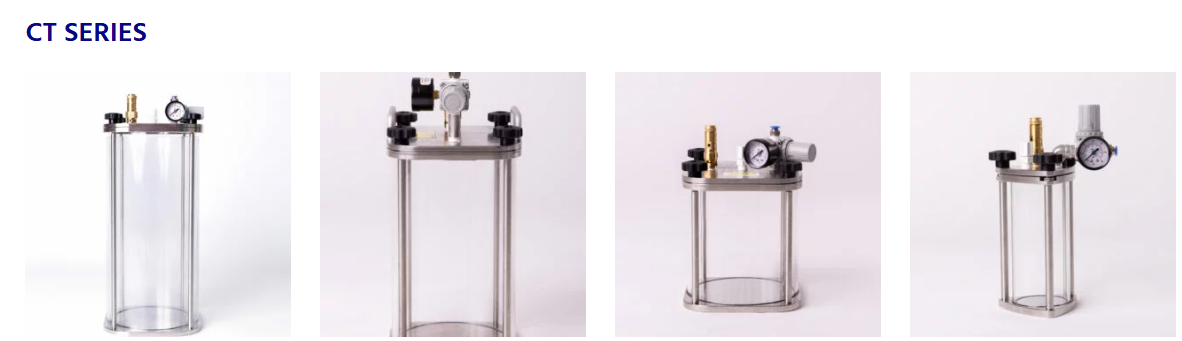

What are Pressure Tank

A Clear Acrylic Pressure Tank is a sealed container made primarily of transparent acrylic material, designed to withstand internal pressure and provide a clear view of its contents or processes occurring inside

Applications

Scientific Research and Laboratories:

Testing fluid dynamics and gas-liquid reactions.

Observing chemical reactions under pressure.

Aquatics and Marine:

Used as pressure chambers in underwater research.

Testing diving equipment or simulating underwater conditions.

Industrial Applications:

Leak testing for components and assemblies.

Pressure testing of materials or equipment.

Medical and Pharmaceutical:

Sterilization under pressure.

Experimentation with controlled environments for biological studies.

Prototyping and Engineering:

Visualization of internal processes in prototypes.

Testing product performance under pressure.

Types

Our pressure vessels are available in a variety of types and configurations to meet the diverse needs of different industries and applications. Here's an overview of the different types we offer:

1. Material Construction

- ●Stainless Steel Vessels:

- ○Grades: Constructed from high-quality stainless steel such as SS304, SS316, and SS316L.

- ○Features: Excellent corrosion resistance, suitable for a wide range of chemicals and temperatures.

- ○Applications: Ideal for pharmaceuticals, chemical processing, food and beverage industries where hygiene and durability are crucial.

- ●Acrylic and Glass Vessels:

- ○Materials: Made from toughened glass or high-strength acrylic.

- ○Features: Transparency allows for visual monitoring of the contents during processing.

Applications: Perfect for laboratory settings, educational purposes, and processes requiring observation.

Design Configurations

- ●Standard Pressure Vessels:

- Features: Designed to handle pressures up to 4 bars or full vacuum.

- Applications: Suitable for storing and processing gases or liquids under pressure in various industrial processes.

- ●Agitated Pressure Vessels:

- Types of Agitation:

- ■Air-Driven Agitators: Ideal for mixing low to medium viscosity fluids.

- ■Electric Agitators: Provide precise control over mixing speeds for more demanding applications.

- Applications: Used in chemical reactions, mixing of formulations

- ●High-Pressure Reactors:

- ○Features: Built to withstand higher pressures and temperatures for specialized reactions.

- ○Applications: Suitable for chemical synthesis, polymerization, hydrogenation, and other high-pressure processes.

3. Capacity and Size Options

- ●Laboratory-Scale Vessels:

- ○Volume Range: From as small as 100 milliliters up to several liters.

- ○Applications: Ideal for research and development, pilot studies, and small-batch production.

- ●Industrial-Scale Vessels:

- ○Volume Range: From 10 liters up to 200 liters or more.

- ○Applications: Designed for large-scale manufacturing processes in industries like pharmaceuticals, chemicals, and food processing.

4. Specialty Vessels

- ●Jacketed Vessels:

- ○Features: Equipped with an outer jacket for heating or cooling the vessel contents.

- ○Applications: Processes requiring precise temperature control, such as fermentations, crystallizations, and exothermic reactions.

- ●Lined Vessels:

- ○Materials: Interior lining with materials like PTFE (Teflon) or glass.

- ○Features: Enhanced resistance to corrosion and chemical reactions.

- ○Applications: Handling aggressive acids, bases, and other corrosive substances.

●Customizable Vessels:

- ○Options: Custom ports, nozzles, fittings, and dimensions to meet specific process requirements.

- ○Applications: Tailored solutions for unique processes in specialized industries.

5. Compliance and Certifications

- ●ASME Certified Vessels:

- ○Standards: Built according to the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

- ○Applications: Required in industries and regions where adherence to strict safety and quality standards is mandatory.

●UN Certified Vessels:

- ○Compliance: Meet United Nations recommendations for the transport of dangerous goods.

- ○Applications: Safe storage and transportation of hazardous materials in compliance with international regulations.

6. Additional Features

●Pressure Relief Systems:

●Instrumentation and Controls:

- ○Includes: Safety valves, rupture disks, and pressure relief vents.

- ○Purpose: Protects the vessel from over-pressurization, ensuring safe operation.

- ○Options: Integration of pressure gauges, temperature sensors, level indicators, and control systems.

- ○Applications: Enables real-time monitoring and precise control of process conditions.

- ●Mobility Solutions:

- ○Features: Mounted on wheels or fitted with handles for easy movement.

- ○Applications: Useful in facilities where equipment needs to be repositioned frequently.

●Sealing Options:

- ○Types: Various sealing mechanisms like clamp closures, bolted lids, or quick-release fittings.

- ○Applications: Ensures secure containment of contents under pressure, suitable for both frequent access and long-term sealing.

7. Specialized Applications

●Vacuum Vessels:

- ○Features: Designed to operate under vacuum conditions.

- ○Applications: Processes like degassing, distillation, and vacuum drying.

●Mixing and Dispersion Vessels:

- ○Features: Equipped with specialized agitators or impellers for mixing powders, slurries, or viscous materials.

- ○Applications: Ideal for creating emulsions, suspensions, or homogenizing mixtures in chemical and pharmaceutical industries.

●Heat Exchanger Vessels:

- ○Features: Incorporate internal coils or external jackets for efficient heat transfer.

- ○Applications: Used in processes requiring rapid heating or cooling, such as exothermic reactions.

By offering a comprehensive range of pressure vessels with various types, materials, and configurations, we ensure that you can find the perfect solution for your specific application. Our vessels are designed with safety, efficiency, and durability in mind, catering to the needs of industries such as:

●Chemical Processing

●Pharmaceutical Manufacturing

●Food and Beverage Production

●Biotechnology

●Environmental and Waste Management

●Research Laboratories

Key Benefits:

●Customization: Tailored designs to meet unique process requirements.

●Quality Assurance: Manufactured to meet or exceed industry standards.

●Expert Support: Our team provides guidance in selecting and configuring the right vessel for your needs.