Laboratory equipment refers to a diverse range of instruments used in laboratories for scientific research, experimentation, and analysis. In the cosmetics industry, this equipment is indispensable for conducting various tests, experiments, and evaluations to ensure the safety, efficacy, and quality of cosmetic products.

Importance of Using Proper Laboratory Equipment

Using proper laboratory equipment For the cosmetics industry is paramount for several reasons:

- Ensuring accurate measurements and analyses

- Maintaining consistency in product formulation

- Complying with regulatory standards and guidelines

- Enhancing product quality and safety

- Facilitating research and development efforts

Types of Laboratory Equipment for Cosmetics

Microscopes

Microscopes are essential for examining the microscopic structure of cosmetic ingredients, formulations, and finished products. They allow cosmetic scientists to analyze the morphology, size, and distribution of particles, as well as the presence of contaminants or impurities.

Spectrophotometers

Spectrophotometers are used to measure the absorption, transmission, and reflection of light by cosmetic samples. They are valuable for color matching, assessing color stability, and determining the concentration of pigments or active ingredients in cosmetic formulations.

Viscometers

Viscometers measure the viscosity or flow behavior of cosmetic liquids and semi-solid formulations. They help cosmetic formulators optimize product texture, consistency, and spreadability, ensuring desirable sensory attributes and user experience.

pH Meters

pH meters are used to measure the acidity or alkalinity of cosmetic solutions and emulsions. Maintaining the proper pH level is crucial for preserving product stability, skin compatibility, and efficacy, especially in skincare and haircare products.

Mixers

Mixers, such as homogenizers and vortexers, are essential for blending and emulsifying cosmetic ingredients. They ensure uniform distribution of active components, stabilizers, and emulsifiers, contributing to product homogeneity and stability.

Emulsifiers

Emulsifiers are specialized equipment used to create stable emulsions by dispersing immiscible phases, such as oil and water, into a homogeneous mixture. They play a vital role in formulating creams, lotions, and serums with desirable texture and appearance.

Centrifuges

Centrifuges are employed for separating components of cosmetic formulations based on their density or molecular weight. They are useful for clarifying solutions, removing insoluble particles, and isolating active ingredients or extracts.

Hot Plates

Hot plates are heating devices used to heat and maintain the temperature of cosmetic samples during various laboratory procedures, such as melting waxes, dissolving solids, or conducting heat-sensitive tests.

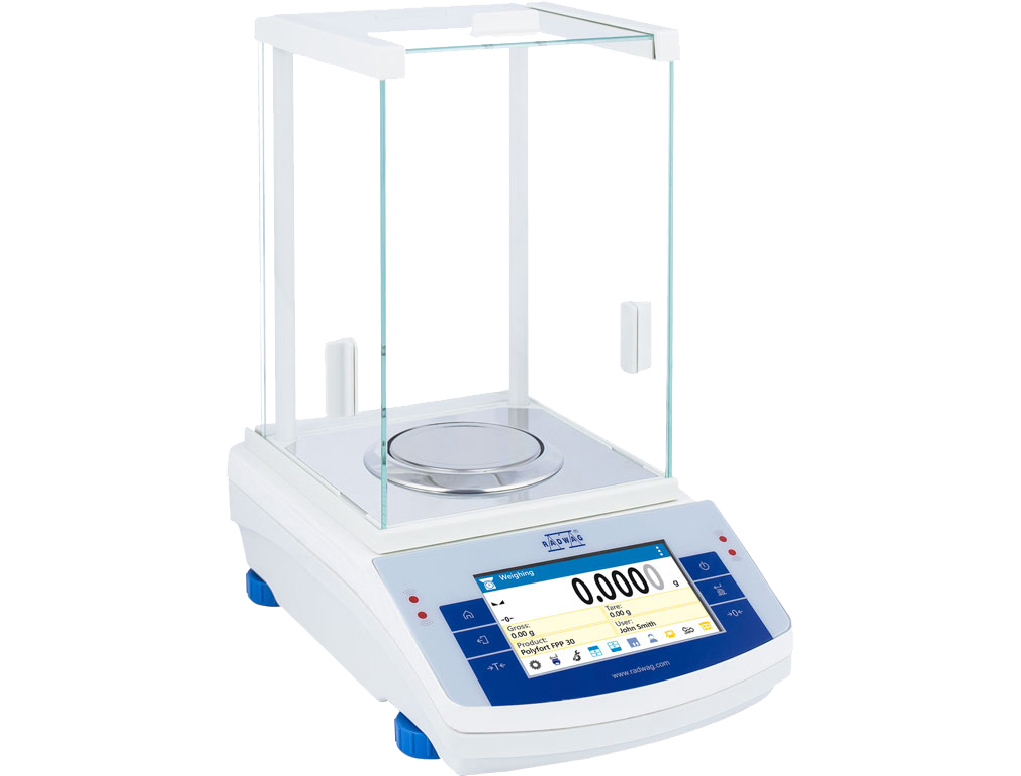

Balance Scales

Laboratory Balance scales are precision instruments used for measuring the mass or weight of cosmetic ingredients and formulations. They ensure accurate dosing and formulation control, critical for achieving consistent product performance and regulatory compliance.

Autoclaves

Autoclaves are sterilization devices that use steam under pressure to eliminate microbial contaminants from equipment, containers, and media used in cosmetic testing and production. Autoclaves are commonly used in the cosmetic industry to sterilize tools and equipment. These devices use high pressure and steam to kill bacteria, viruses, and other microorganisms, ensuring that tools are safe for use on clients' skin. Autoclaves are crucial for maintaining hygiene standards and preventing the spread of infections in cosmetic procedures. They're especially important for tools like tweezers, scissors, and needles that come into direct contact with the skin. Regular sterilization with autoclaves helps cosmetic professionals uphold the highest standards of safety and cleanliness in their practice.

Chromatography Equipment

Chromatography equipment, including gas chromatographs (GC) and high-performance liquid chromatographs (HPLC), are analytical tools used to separate, identify, and quantify components in complex cosmetic matrices. They are valuable for analyzing fragrance compounds, preservatives, and other volatile or semi-volatile ingredients.

Particle Size Analyzers

Particle size analyzers are instruments used to measure the size distribution and morphology of particles in cosmetic suspensions, emulsions, and powders. Understanding particle size characteristics is essential for optimizing product stability, texture, and performance.

Ovens and Incubators

Laboratory Ovens and incubators are temperature-controlled chambers used for drying, curing, or incubating cosmetic samples under controlled environmental conditions. They are essential for studying the effects of temperature on product stability, shelf life, and microbial growth.

Filtration Systems

Filtration systems are employed for clarifying cosmetic solutions, removing particulate matter, and sterilizing liquids. They help maintain product clarity, purity, and safety by removing contaminants and microorganisms.

Ultrasonic cleaner for cosmetic tools

An ultrasonic cleaner is an excellent tool for cleaning cosmetic tools such as makeup brushes, tweezers, and metal implements like eyelash curlers or scissors. These cleaners use high-frequency sound waves to create millions of tiny bubbles in a cleaning solution. As these bubbles collapse, they produce a scrubbing action that effectively removes dirt, oil, and makeup residues from the tools.

How Each Type of Equipment Is Used in Cosmetic Testing and Formulation

- Microscopes enable the examination of ingredient morphology and product microstructure.

- Spectrophotometers aid in color analysis and quantification of pigment concentrations.

- Viscometers assess product viscosity and rheological properties.

- pH meters ensure proper pH adjustment for product stability and skin compatibility.

- Mixers and emulsifiers facilitate ingredient blending and emulsion formation.

- Centrifuges separate components based on density or molecular weight.

- Hot plates provide controlled heating for various laboratory procedures.

- Balance scales ensure accurate ingredient measurement and formulation.

- Autoclaves sterilize equipment and media to maintain product microbiological safety.

- Chromatography equipment analyzes the composition of cosmetic formulations.

- Particle size analyzers determine the size distribution of particles in cosmetic products.

- Ovens and incubators study the effects of temperature on product stability and performance.

- Filtration systems clarify and sterilize cosmetic solutions for product safety.

Considerations When Selecting Laboratory Equipment for Cosmetics

When selecting laboratory equipment for cosmetics, several factors should be considered:

- Compatibility with cosmetic formulations and testing requirements

- Accuracy, precision, and reliability of measurements

- Ease of use, maintenance, and calibration

- Compliance with regulatory standards and industry guidelines

- Cost-effectiveness and return on investment

- Availability of technical support and training resources