An ultrasonic cleaner is a cleaning device that uses ultrasound (usually from 20–400 kHz) and an appropriate cleaning solvent (sometimes ordinary tap water) to clean delicate items. Ultrasonic cleaners are used to clean metal, plastic, glass, ceramic, dirt, grease oil and more. Ultrasonic cleaning saves manual cleaning, shortens cleaning time, Can be cleaned in narrow places, small holes that can not be cleaned manually with a brush.

How long is the process?

Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned.What is it good for?

Ultrasonic cleaners are used to clean many different types of objects, including jewelry, lenses and other optical parts, watches, dental and surgical instruments, tools, coins, fountain pens, golf clubs, window blinds, firearms, musical instruments, industrial parts and electronic equipment. They are used in many jewelry workshops, watchmakers' establishments, and electronic repair workshops.Which reagents are needed for the process?

The ultrasound can be used with just water, but use of a solvent appropriate for the item to be cleaned and the soiling enhances the effect.

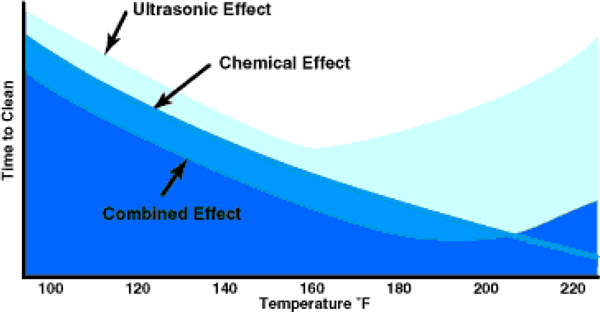

Combining the chemical cleaning effect with the ultrasonic effect contributes to Maximizing the Overall Cleaning Effect.

Types of ultrasonic cleaners:

- DCG series bath with DEGASING function to neutralize the bubbles that are in the liquid and interfere with cleaning,DEGASING functions increase the cleaning power and shorten the cleaning time.

- DCS series bath. In addition to the DEGASING function, it has a SWEEP function that improves the uniformity of cleaning in the bath,By playing small at the ultrasonic frequency, it prevents dead areas from vibrations. Improves cleaning in large quantities of small parts.

- Two-frequency DCF series bath. The higher the frequency, this means the bubbles are smaller and smaller parts and small holes can be cleaned.The bath also includes the DEGASING function.

Taypical Ultrasonic Cleaners applications:

Ultrasonic cleaners create by cavitaion millions of microscopic bubble implosions and remove contaminants from metal, plastic and ceramic surface .

Cleaning Tattoo Needles and Tubes

Cleaning Laboratory Glassware

Cleaning Printed Circuit Boards

Cleaning used ink cassettes

Cleaning Plastic Injection Molds

Laboratory Sample Preparation and degassing

Cleaning Automotive Marine and Aerospace , Carburetors and Engine Parts

Cleaning Weapons parts .

Cleaning Tattoo Needles and Tubes

Cleaning Jewelry

Cleaning Watches & Clocks

Cleaning Surgical Instruments

Cleaning Dental Instruments

Cleaning Veterinary Instruments

Cleaning Circuit Boards

Warnings for use in ultrasonic Cleaner work

- Do not use flammable or explosive cleaners.

-Fill up to 20 mm from the top, a bath that is not full may burn the radiators and transducers.

-Metal and metal particles must not touch the bottom of the bath, the transducers produce vibrations at the bottom of the bath. Contact with particles Metal will cause invisible holes to form and leak liquids to control cards, transducers and burn them. It is therefore important to empty and clean the bath of dirt, place the parts that are cleaned in the basket and not directly on the bottom of the bath.

- For jewelers who clean necklaces, make sure that the necklace does not touch the bottom of the bath.

Heat over time shortens the life of the transducer and its capacity. It is advisable not to work in consecutive cycles. After the timer finishes a work cycle wait half an hour until the next work cycle.

- Do not boil water and pour into the bath.

Sweep Function

To avoid standing waves and resonance in an ultrasonic cleaning bath, it is beneficial to have a sweep function. The sweep function is a feature in ultrasonic cleaners that modulates the frequency of the sound waves generated by the transducers.

When ultrasonic waves pass through a cleaning solution, they can reflect and interfere with each other, leading to the formation of standing waves and resonance patterns. These standing waves can create areas of high and low pressure within the cleaning bath, resulting in uneven cleaning and potential damage to delicate items.

The sweep function addresses this issue by continuously and automatically varying the frequency of the ultrasonic waves over a certain range. By sweeping the frequency, it prevents the formation of stationary nodes and antinodes that cause standing waves. Instead, the energy is dispersed more evenly throughout the cleaning bath, resulting in a more uniform distribution of ultrasonic cleaning action.

The sweep function helps to minimize the risk of hotspots or dead zones in the cleaning bath, improving the overall effectiveness of the cleaning process. It ensures that all parts or items being cleaned are exposed to a consistent and uniform distribution of ultrasonic energy.

Custom ultrasonic baths

MRC supplies and manufactures custom ultrasonic baths, according to a specific size according to customer requirements.