Vacuum technology is important in various industries, ranging from manufacturing and pharmaceuticals to research and development. Among the different types of vacuum pumps, dry vacuum pumps have emerged as a significant innovation, revolutionizing the way vacuum systems operate. In this article, we will explore the fascinating world of dry vacuum pumps, their advantages, and their growing importance in diverse applications.

Understanding Dry Vacuum Pumps

Traditional vacuum pumps rely on oil as a lubricant and sealant, utilizing it to create a vacuum by removing gas molecules from a sealed chamber. However, this method is not without drawbacks. Oil-sealed pumps require regular maintenance, oil changes, and disposal, leading to increased operational costs and environmental concerns. Additionally, oil contamination can adversely affect sensitive processes, making them unsuitable for specific applications.

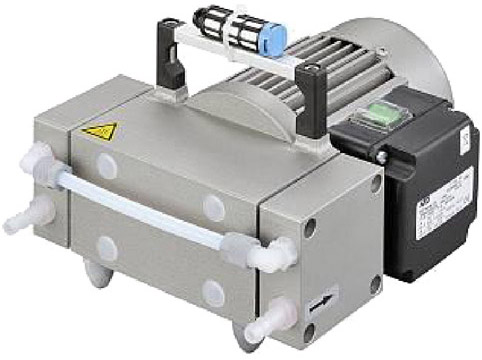

Dry vacuum pumps, on the other hand, offer a cleaner, more efficient, and environmentally friendly alternative. As the name suggests, these pumps operate without the need for oil lubrication or sealing, making them virtually maintenance-free and significantly reducing the risk of oil contamination.

Operating Principles

Dry vacuum pumps employ various mechanisms to create a vacuum. One common design is the claw pump, which uses a pair of claw-shaped rotors to compress gas and create a pressure difference. The rotors interlock but do not come into contact with each other, eliminating the need for lubrication. As the rotors rotate, gas is trapped and compressed before being expelled.

Another design is the screw pump, which utilizes two intermeshing screws to create a vacuum. As the screws rotate, gas is trapped and transported towards the exhaust port, resulting in efficient compression and extraction.

Advantages of Dry Vacuum Pumps

- Improved Efficiency: It offers higher pumping speeds and improved volumetric efficiency compared to their oil-sealed counterparts. Their advanced designs allow for faster evacuation times, increasing productivity in various applications.

- Minimal Maintenance: The absence eliminates the need for frequent oil changes, reducing downtime and maintenance costs. This advantage makes them particularly attractive for industries that require uninterrupted operation.

- Reduced Contamination Risks: With oil-free operation, dry vacuum pumps eliminate the risk of oil contamination in sensitive processes such as semiconductor manufacturing, analytical instrumentation, and food processing. This ensures cleaner and more reliable results.

- Environmental Friendliness: By eliminating the need for oil lubrication and disposal, dry vacuum pumps contribute to a cleaner and more sustainable environment. They reduce waste generation, minimize carbon footprint, and comply with stricter environmental regulations.

Applications of Dry Vacuum Pumps

The versatility of dry vacuum pumps allows them to be used across a wide range of industries and applications. Some notable examples include:

- Semiconductor Manufacturing: They are vital in semiconductor fabrication, where clean environments are essential. They enable efficient wafer processing, ensuring the highest quality and reliability in the production of microchips.

- Pharmaceuticals: play a critical role in processes such as freeze-drying, distillation, and sterilization. Their oil-free operation ensures product integrity and purity.

- Research and Development: Used in laboratories and research facilities for various applications, including electron microscopy, mass spectrometry, vacuum ovens, and vacuum filtration.

- Food and Beverage: its help maintain the quality and extend the shelf life of food products by facilitating vacuum packaging, freeze-drying, and vacuum distillation processes.

Uses of Dry Vacuum Pumps

Dry vacuum pumps are versatile devices with numerous applications across various industries. Here are some common uses of dry vacuum pumps:

- Semiconductor Manufacturing: Essential in semiconductor fabrication processes. They play a critical role in maintaining clean environments and removing contaminants during the production of microchips. They enable the precise control of pressure levels required for deposition, etching, and other semiconductor manufacturing steps.

- Pharmaceuticals: In the pharmaceutical industry, dry vacuum pumps are employed in multiple processes. They are used for freeze-drying, where moisture is removed from pharmaceutical products under vacuum conditions. Also, find application in distillation processes, where they aid in the separation and purification of different compounds. Moreover, they are utilized in sterilization procedures, ensuring the removal of air and microorganisms from equipment and packaging.

- Research and Development: Used in research laboratories and development facilities. They power various analytical instruments such as mass spectrometers, electron microscopes, and surface analysis tools. These pumps create the required vacuum conditions for accurate measurements, sample preparation, and analysis in scientific research.

- Food and Beverage Industry: They are used for vacuum packaging, which helps extend the shelf life of perishable products by removing air and reducing oxidation. Dry vacuum pumps also enable freeze-drying processes in food preservation, where moisture is removed under low temperatures and vacuum conditions, preserving the nutritional value and quality of the food.

- Environmental Applications: Dry vacuum pumps find applications in environmental monitoring and analysis. They are used in air sampling equipment to collect air samples for pollutant analysis and monitoring. The pumps create a vacuum to draw in air samples, ensuring accurate measurements of air quality and pollutant levels.

- Industrial Processes: They are employed in vacuum distillation for the separation of components in chemical and petrochemical industries. Also, facilitate the degassing of oils and resins, removing trapped air and moisture to enhance product quality and performance. Furthermore, they are used in vacuum drying processes, removing moisture from materials and products without causing thermal damage.

- Energy and Power Industries: Dry vacuum pumps are crucial in the energy and power sectors. They play a key role in vacuum furnace systems, where they create and maintain vacuum conditions required for heat treatment and metal processing. Dry vacuum pumps are also utilized in power plants for turbine evacuation, ensuring the efficient and reliable operation of power generation systems.

These are just a few examples of the extensive range of applications for dry vacuum pumps. Their versatility, reliability, and oil-free operation make them indispensable in various industries, enabling precise control of vacuum conditions and contributing to efficient and high-quality processes.