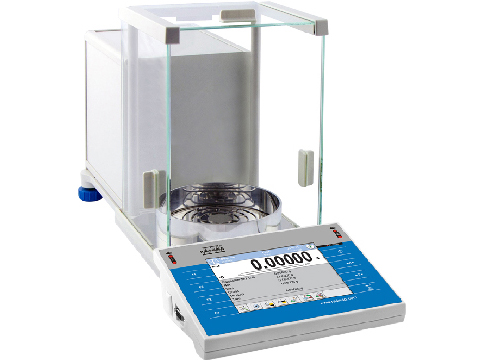

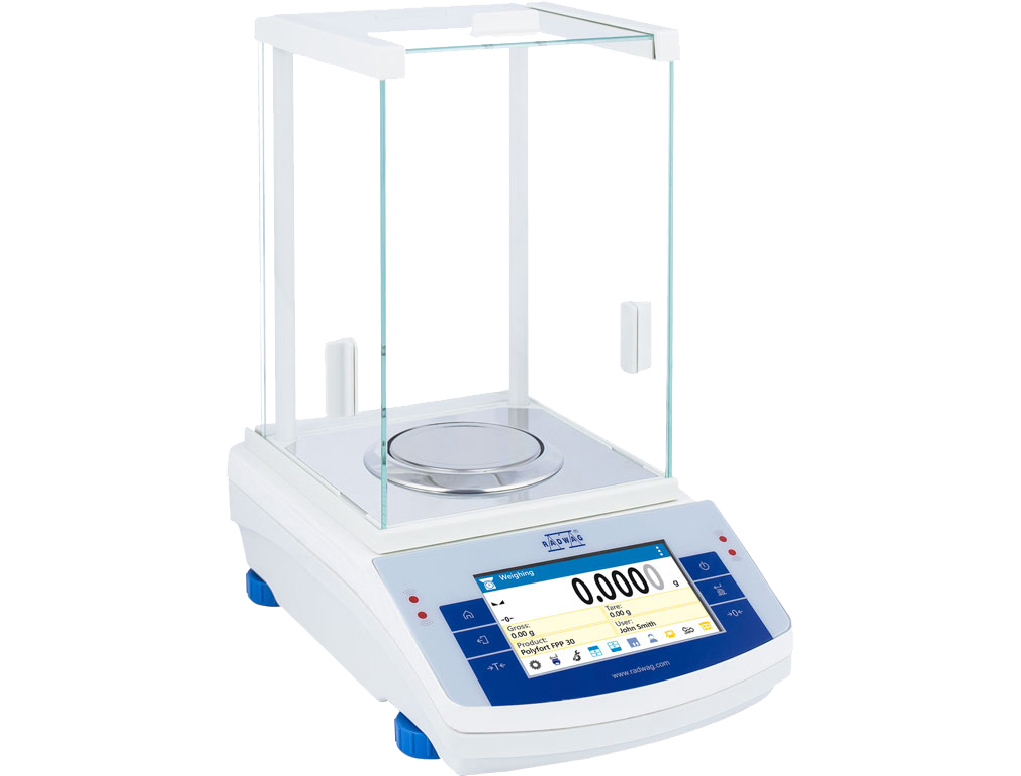

Analytical balances are a cornerstone in various industries where precision and accuracy are paramount. These delicate instruments play a crucial role in ensuring that substances are measured with the utmost precision, impacting fields from pharmaceuticals to scientific research. In this article, we delve into the specifics of what materials can be weighed in analytical balances and why these instruments are indispensable.

Materials Suitable for Analytical Balances

Powders and Granules

Analytical balances are adept at weighing fine powders and granules, making them indispensable in pharmaceutical and chemical industries. The balance's sensitivity allows for accurate measurement even when dealing with minute quantities.

Liquids

Liquid samples, often challenging to weigh accurately, pose no problem. The instrument's ability to account for the density of liquids ensures precise measurements, crucial in applications like formulation in the pharmaceutical industry.

Small Objects

From precious gems to microelectronic components, analytical balances can handle small and delicate objects with precision. This capability makes them invaluable in jewelry manufacturing and electronics industries.

Mass of Solids: Used to measure the mass of solid substances. This could include chemicals, powders, crystals, or any other solid material.

Mass of Liquids: By using appropriate containers, They can also be used to measure the mass of liquid substances. This is usually done by weighing the container with the liquid and then subtracting the mass of the empty container.

Chemical Reagents: Precise measurements of chemical reagents are crucial in many laboratory experiments. Analytical balances ensure accurate amounts of reagents are used, which is essential for obtaining reliable results.

Pharmaceuticals: In pharmaceutical laboratories, They are used to measure the mass of active ingredients and other components in drug formulations to ensure the right dosage and quality.

Food and Beverage Testing: Analytical balances are employed in the food and beverage industry to measure the mass of ingredients during production and quality control processes.

Environmental Samples: When analyzing environmental samples, such as soil or water, analytical balances are used to measure the mass of sample components for various testing purposes.

Density Determination: Used in conjunction with density kits to determine the density of a substance by measuring both mass and volume.

Calibration Weights: Used to calibrate other weighing instruments by using precision calibration weights.

Importance of Sample Size

Analytical balances thrive on small sample sizes. Their sensitivity is optimized for measuring quantities in the sub-milligram range. This feature is particularly advantageous in industries where minimizing sample usage is crucial.

Appropriate Equipment

- Glassware: Glass containers are commonly used in analytical laboratories. They are inert and do not react with most substances. When using glassware, ensure it is clean and free of residues that could affect the measurements.

- Plastic Weighing Boats or Pans: Disposable plastic weighing boats or pans are often used to hold substances during weighing. They are lightweight, disposable, and can be used to prevent contamination between different samples.

- Metal Forceps or Spatulas: When transferring substances to and from the weighing pan, use non-reactive metal forceps or spatulas. Stainless steel is a common choice due to its inert nature.

- Anti-static Tools: In environments where static electricity can be a concern, consider using anti-static tools to prevent the accumulation of static charges that might affect the weighing process.

- Clean and Dry Environment: Ensure that the environment around the balance is clean and dry. Dust and moisture can affect the accuracy of measurements.

- Pipettes and Burettes: For liquids, use calibrated pipettes or burettes made from materials that are chemically inert, such as borosilicate glass.

- Calibration Weights: Regularly calibrate the analytical balance using certified calibration weights. These weights should be handled with clean, dry hands or with anti-static tools to maintain their accuracy.

- Static Elimination Tools: In environments where static electricity is a concern, use tools designed to eliminate or reduce static charges, such as ionizing blowers.

- Proper Techniques: Train users in proper weighing techniques to minimize errors. This includes taring the balance, allowing substances to reach room temperature before weighing, and avoiding unnecessary drafts.

- Routine Maintenance: Follow the manufacturer's guidelines for routine maintenance of the analytical balance. Regular cleaning and calibration are essential for accurate and reliable measurements.

Precision and Accuracy in Weighing

Understanding the terms precision and accuracy is fundamental when working with analytical Laboratory balances. Precision refers to the instrument's ability to provide consistent results, while accuracy is its ability to provide measurements close to the true value. Analytical balances excel in both aspects, ensuring reliable data in every weighing operation.