Laboratory Furnaces 1000-3000degC by mrc feature temperatures up to 3000°C and sealed designs that support atmosphere control necessary for advanced processes. laboratory furnaces use a heat source to heat a sample within the furnace chamber.Laboratory furnaces offer precise temperature control, ensuring that experiments are carried out with repeatability and reliability. When working with temperatures in the range of 1000°C to 3000°C, the quality of the furnace significantly impacts the outcomes of the process, especially in high-tech industries.

Types of Laboratory Furnaces

Ashing furnace-designed to remove matrix constituents that might interfere with the measurement of the analyte

Top loading laboratory furnaces-processed is loaded through the top.

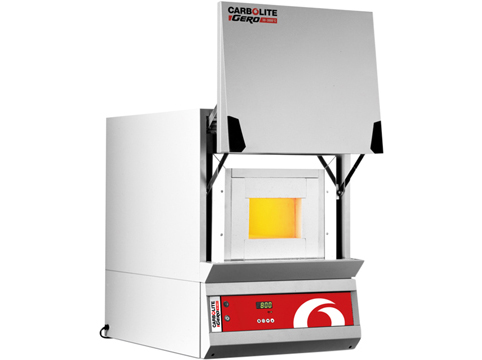

Box Furnaces-the furnace has a box shape and a box-shaped interior.Box furnaces are versatile and can heat large samples. They are often used for heat-treating metals, as well as for general-purpose laboratory applications.

Choosing the Right Laboratory Furnaces

When we need a furnace for a laboratory we need to look at the following: process temperature, width or tube outer diameter, length of the chamber or tube, and height.

Application of Laboratory Furnaces

A laboratory furnace is very important in the laboratory, it performs many important roles. They are found a lot in industry and science

Laboratory furnaces can also be used for solvent removal, sterilizing, evaporation, polymer curing, and polyimide baking.

Materials Science

In materials science, laboratory furnaces are used to test the properties of materials at different temperatures, including melting points, thermal expansion, and tensile strength.

Metallurgy

Metallurgical laboratories rely on high-temperature furnaces for smelting metals, testing alloys, and refining ores.

Ceramics and Glass Production

Furnaces are vital in the ceramics and glass industries for firing products and ensuring the right crystalline structure and material properties.

Chemical Research

Laboratory furnaces are also employed in chemical research for reactions that require precise heating and controlled environments.

Environmental Testing

Furnaces help in analyzing samples that need to be subjected to extreme heat to determine their environmental stability or chemical composition.

Temperature Ranges and Capabilities of Laboratory Furnaces

Laboratory Furnaces: 1000°C to 3000°C

The temperature capabilities of laboratory furnaces are crucial, as different scientific processes require specific temperature ranges. Furnaces in the range of 1000°C to 3000°C are used in advanced research applications where controlled heat treatments are essential.

Applications at 1000-1500°C

Furnaces in this range are typically used for processes like annealing, where metals and alloys are softened or made more ductile. They’re also used in ceramics to fire clay-based products and in glassmaking industries.

Applications at 1500-2000°C

As we move to higher temperatures, 1500°C to 2000°C furnaces are ideal for sintering processes, where powdered materials are fused together without melting entirely. These furnaces are also used in the manufacturing of refractories and other heat-resistant materials.

Applications at 2000-3000°C

At the upper end of the temperature spectrum, 2000°C to 3000°C furnaces are used in cutting-edge fields like the production of ultra-high-temperature ceramics and the processing of advanced composite materials for aerospace applications.

More Furnaces&Ovens:

Carbolite manufacturer