MRC offers a broad range of vacuum pumps for chemical and biological laboratories for various applications: Rotary evaporators, vacuum ovens, reactors, filtration, gel dryers, freeze dryers, concentrators, manifolds and cell culture, aspiration applications.Vacuum pumps remove gas from a sealed volume to leave a partial vacuum. Fluids then rush into the vacuum due to the difference in pressure gradients.

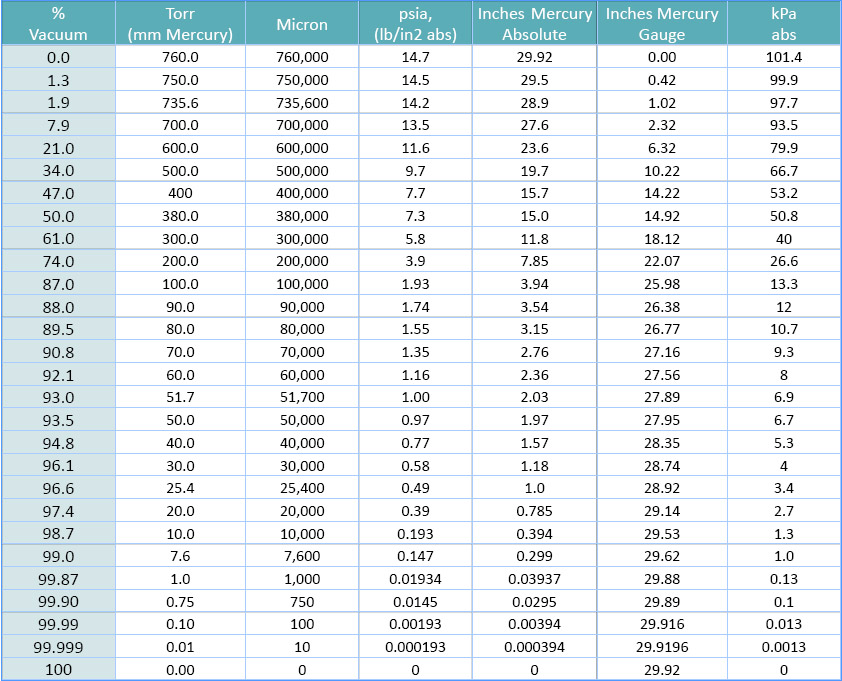

For converting between common vacuum units:

To our peristaltic pumps

Types and applications of vacuum pumps

Vacuum pumps differ from each other in the method of pumping, the depth of the vacuum and the materials from which they are made.

- Oil vacuum pumps are suitable for vacuum ovens and lyophilizers (freeze-drying).

-Vacuum pumps (dipregma) without oil -Manufacture vacuum in desiccators and filtration -In a single vessel or manifold with several filtration channels.These pumps are made of Teflon protected from aggressive gases and liquids. They are designed to work with solvents infiltration and extraction, with a rotary evaporator.

-Turbo vacuum pumps-Deep vacuum in vacuum ovens.

-Scientific Instruments.

-Thin Film Deposition.

-Medical & Pharma.

-Mobility.

-Semiconductor

-Photovoltaics

-Energy

-Process Industry

-Industrial Vacuum

Vacuum pumps for laboratories are designed:

-aspiration or filtration of liquid or suspended samples

-To cause or regulate the evaporation of solvents by reducing the vapor pressure

-To collect gas samples from test chambers or the atmosphere

-Cause negative pressure to prevent the exit of potentially hazardous samples.

Specifications to consider

-Type of pump, with or without oil

-Engine speed (RPM)

-Horsepower (hp)

-Noise level (dB)

-Pipe diameter (mm)

-Net weight (kg)

Measure

(cfm) (m3 / h) are the two standard dimensions.

Primary Manufacturer:

Welch

Welch is a leading manufacturer of high quality vacuum pumps

Welch is a manufacturer of vacuum pumps in a variety of types

Welch has over 100 years of experience